小作文1(30 mins, 189 words)

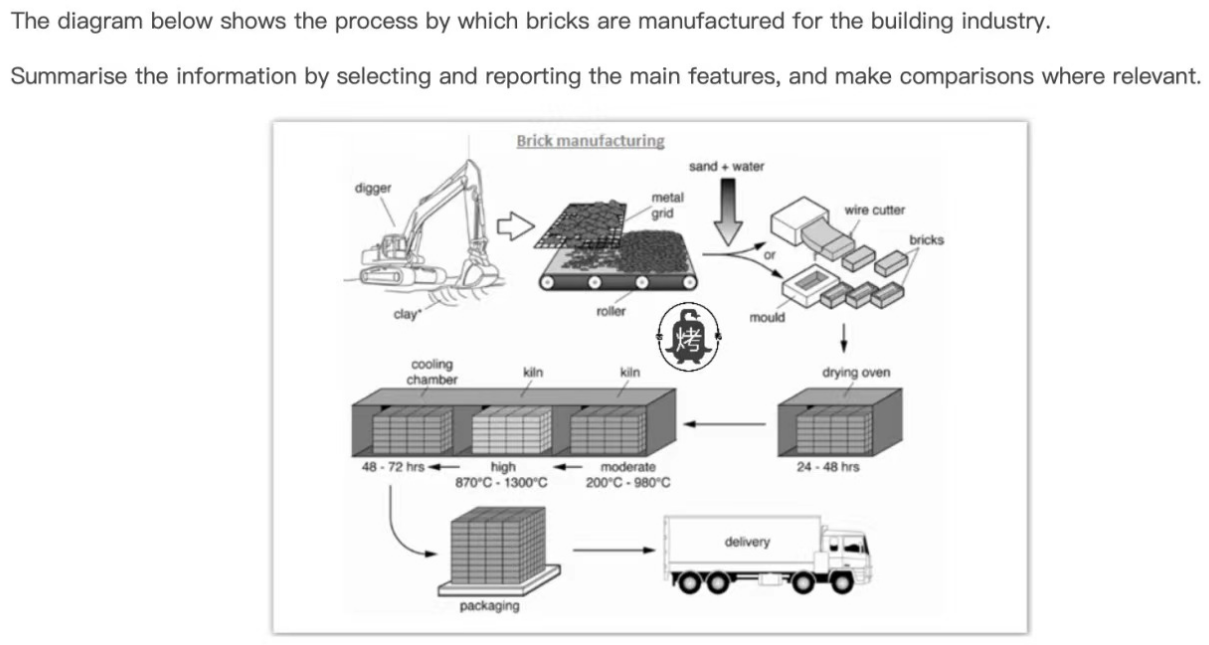

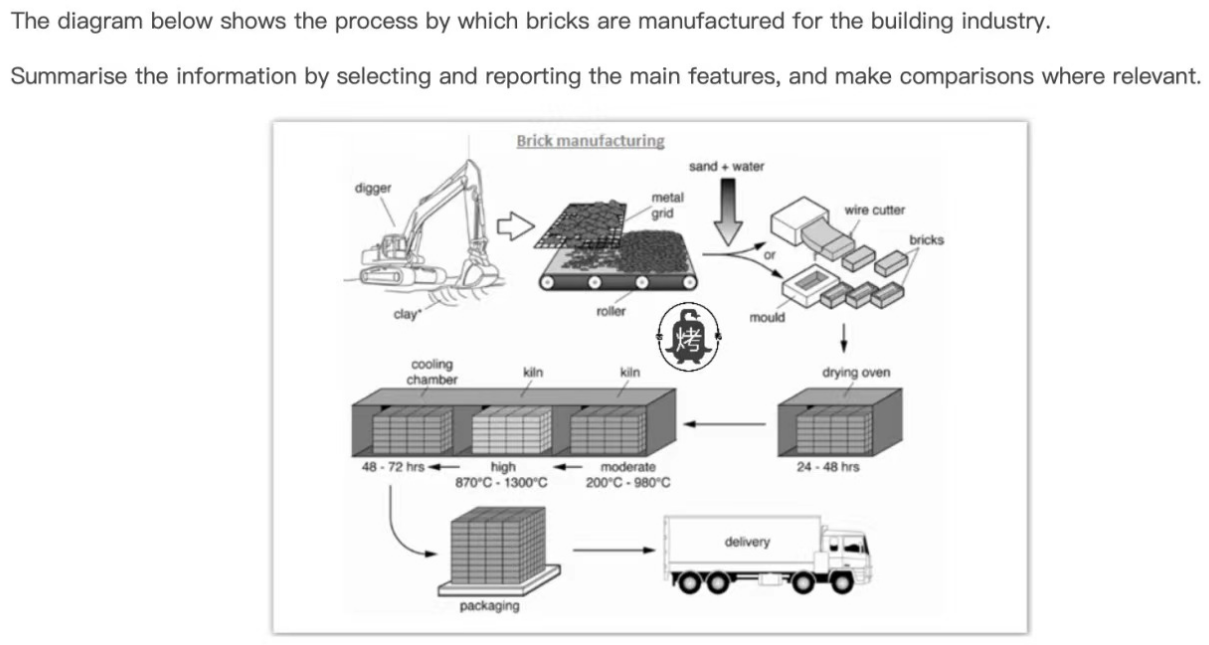

The flow chart provides an overview of the process about the production of bricks for the building industry. Overall, the process is made uop of seven steps.

First, the clay is dug by a digger to provide the material of bricks. After that, it is put to a metal grid to filter, and the clean clay can sent to the next step by a roller. Then, after sand and water are added to the clay, the initial bricks can be generated by a machine and a wire cutter, or by a mould directly. Next, the bricks need to be dried oven for 24 to 48 hours. In the next step, bricks are turned to the kiln to warm up in the moderate temperature of 200℃ to 980℃, and then are turned to anthor kiln to do again in a much higher temperature of 870℃ to 1300℃, and are ended after 48 to 78 hours cool in the cooling chamber. Finally, the bricks are packed and sent to different areas by trucks.

To sum up, the process starts from clay and ends up with bricks. It is a complex process.

小作文2(27 mins, 182 words)

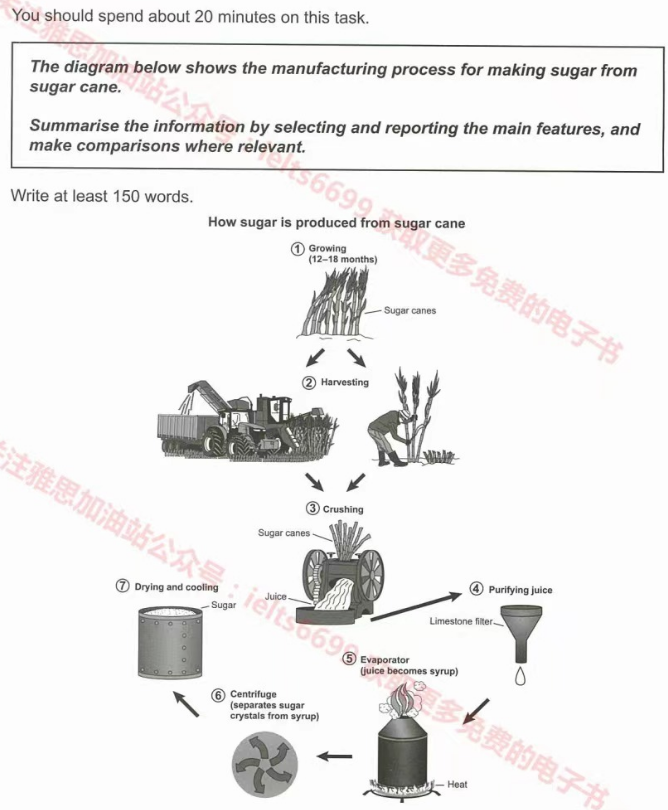

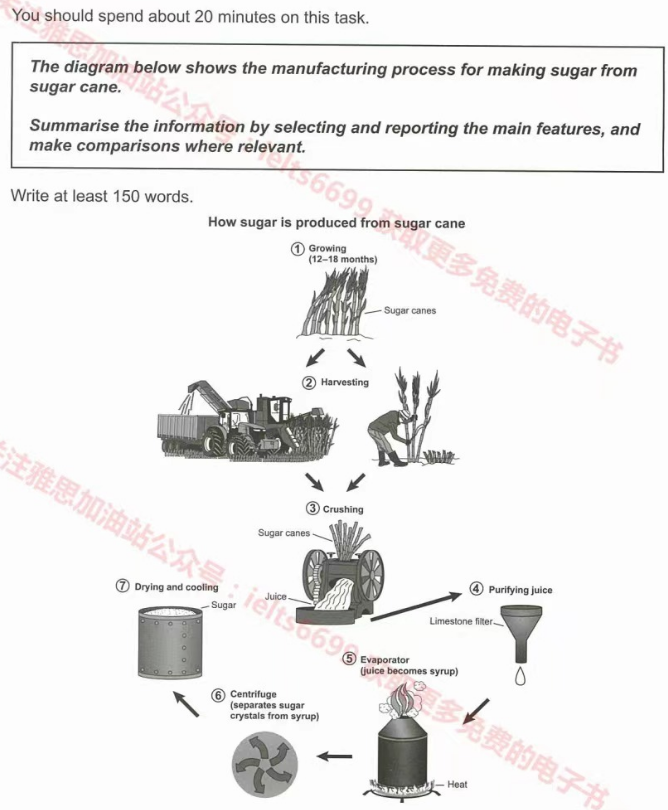

The flow chart provides an overview of the process of sugar production from sugar cane. Overall, the process is made up of seven steps.

First, the sugar canes are planted and take about 12 to 18 months to grow. Until they grow much taller, that is the time to harvest, farmers will use an agricultural machine to harvest or just cut the sugar canes by knife. After that, the remain sugar canes can grow again, and the others are crushed to produce juice by a machine, and the limestone filter is used to purify the juice to make well preparation to the next step. Then, the evaporator, which is heated by fire, is used to make the juice become syrup which is suitable to the centrifuge. In the next, the separates sugar can be separated from syrup by a centrifuge, which is the initial state of sugar. Finally, the sugar is made successfully and stored in a big container after drying and cooling.

To sum up, the process starts from sugar canes and ends up with sugar. It is a complex process.